News

Stay informed with the latest developments from Sekisui Foam Australia.

Sekisui Donates to Beyond Blue in Support of Mental Health Services

Sekisui chooses to forgo traditional Christmas gifts for our customers in favour of making a meaningful impact through charitable donations.

Sekisui Foam Australia Donates to Cancer Care Centre

Sekisui Foam Australia has dug deep to support cancer patients in the Far North Queensland region with a $15,000 donation to the Far North Queensland Hospital Foundation, Liz Plummer Cancer Care Centre.

Industry Alert – NCC2019 ASNZS4859.1.2018 Compliance

Insulation Australasia recently highlighted the fact that “May 2020 marks a significant milestone for change in the Australian Insulation industry as it is the drop dead date for compliance to the revised insulation standard AS/NZS 4859.1.2018 under NCC 2019.”

Thermobreak – Setting the standard for over 30 years

Ausrail Plus 2019, Come and say hi

Interested in Thermobreak transit vehicle insulation? Come and say hi during the Ausrail Plus exhibition at ICC Sydney from December 3-5 2019, Stand 451.

Sekisui named again in Global 100 Most Sustainable Corporations

Sekisui Chemical Group has again been named in the Global 100 Most Sustainable Corporations in the World.

Come & see us at AHR EXPO 2019 – Booth B1667

The latest Thermobreak insulation product innovations from Sekisui Foam will be showcased at the 2019 AHR Expo in Atlanta, “The world’s largest HVACR marketplace”.

Sekisui named in 2018 Global 100 Most Sustainable Corporations

Sekisui Chemical Group has been named in the Global 100 Most Sustainable Corporations in the World. The Global 100 index ranks major companies from all sectors around the world in areas such as environmental, social and economic performance.

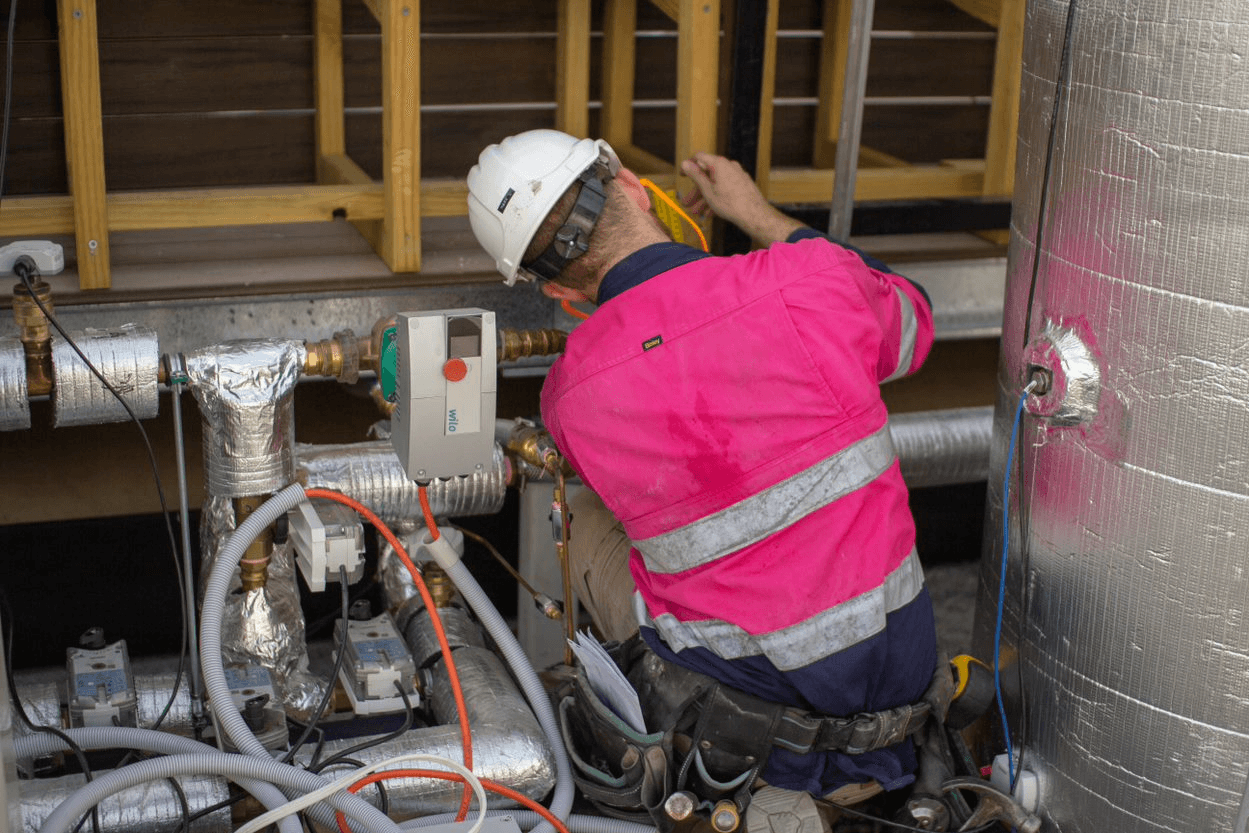

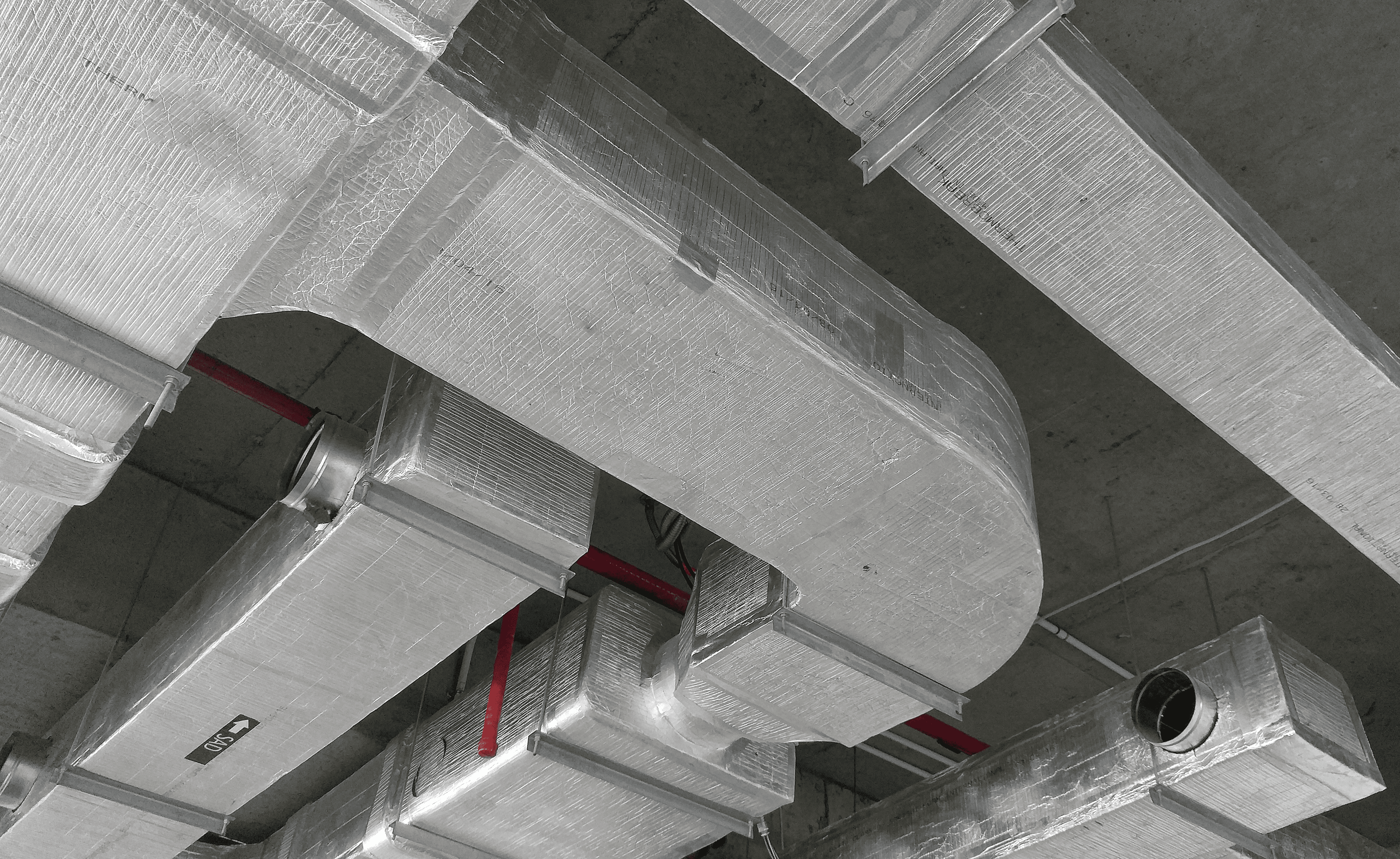

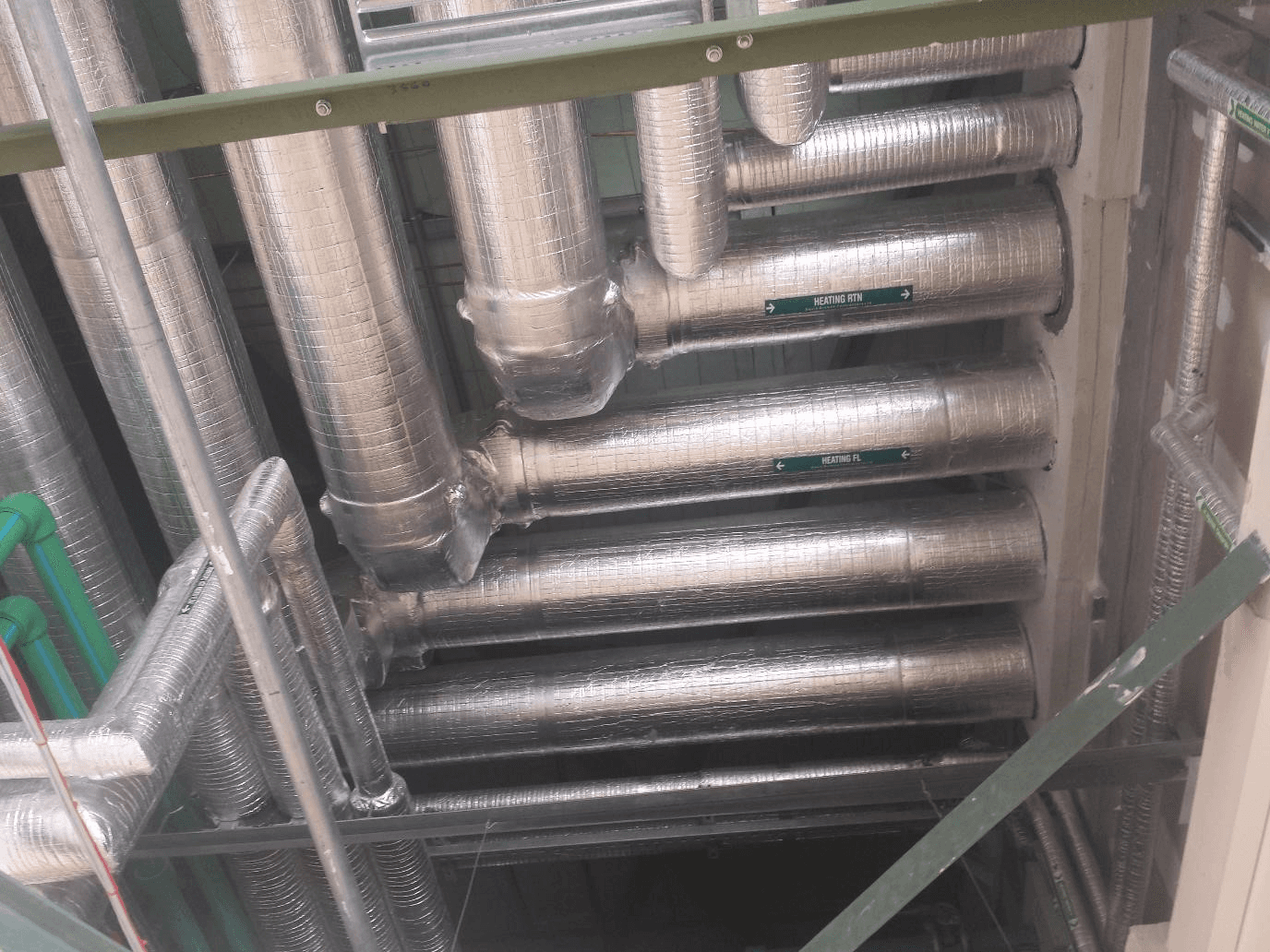

Thermal Insulation Engineered to Perform

Building services engineers bring buildings to life. Thermobreak Insulation is engineered to maintain the long lasting health and efficiency of buildings and is the preeminent insulation solution for building services engineers.

FM Approved Thermobreak No-Clad Pipe Insulation

Thermobreak No-Clad, the ultra-tough external pipe insulation from Sekisui Foam Australia provides FM Approval certification for pipe sizes up to 8” IPS and 50mm wall thickness.

Sekisui Foam Australia achieves OHSAS 18001

Sekisui Foam Australia has achieved certification to the OHSAS 18001:2007 standard for Occupational Health and Safety Management.

Codemark Third Party Certification and Thermobreak

CodeMark is a third-party certification scheme for building products and systems, developed and managed by the Australian Building Codes Board (ABCB). CodeMark certification provides reliable evidence of a building product or system complying with the Building Code of Australia (BCA).